In the past decade, digitalization and the rapid evolution of digital technologies have transformed industries across the globe. Businesses are constantly rethinking how they operate to remain competitive. Among these advancements, the integration of edge artificial intelligence (Edge AI) has emerged as a game-changer in addressing specific business challenges across various sectors. In particular, the semiconductor industry is at the forefront of this digital transformation, leveraging cutting-edge technologies to enhance factory automation and streamline core processes such as quality management.

Building a Digital Tacit Knowledge Platform

To meet the demands of modern semiconductor manufacturing, Infineon has developed the “Smart Semiconductor Manufacturing Assistant,” an innovative project demonstrator. This initiative centers around creating an explainable AI model based on historical production quality data, effectively acting as a digital tacit knowledge platform. The primary goal is to accelerate quality improvements and drive smarter decision-making in manufacturing.

This platform enables Infineon to:

- Rapidly identify and predict factors contributing to quality issues.

- Pinpoint and prioritize process improvements for enhanced quality.

- Generate actionable recommendations to address inefficiencies.

- Train and test AI models using historical production quality data.

- Provide deeper insights into factors influencing key quality metrics.

- Select the most practical and impactful improvement actions.

- Deliver real-time recommendations to assist engineers in their workflows.

By integrating these capabilities, the platform empowers manufacturers to transition from reactive problem-solving to proactive quality management.

Infineon’s Role and the Edge AI Project

As part of the EdgeAI project, Infineon Technologies Austria AG aims to develop a robust decision-support tool that establishes AI-driven causal links across diverse production databases, including document data, production records, and process diagrams. This innovative EdgeAI solution is being implemented in the demonstrator within the “Digital Industry” value chain, targeting three key objectives:

- Boost production efficiency: Minimize delays and inefficiencies to optimize throughput.

- Ensure high-quality output: Maintain stringent quality standards in manufacturing processes.

- Foster sustainability: Support semi-autonomous production environments that prioritize resource efficiency.

Infineon’s broader vision involves expanding this digital tacit knowledge platform across its front-end factory cluster under the company’s “One Virtual Fab” concept. This approach aims to amplify the platform’s impact and contribute to a more sustainable, resilient, and competitive European semiconductor industry.

Addressing Complex Challenges in Semiconductor Manufacturing

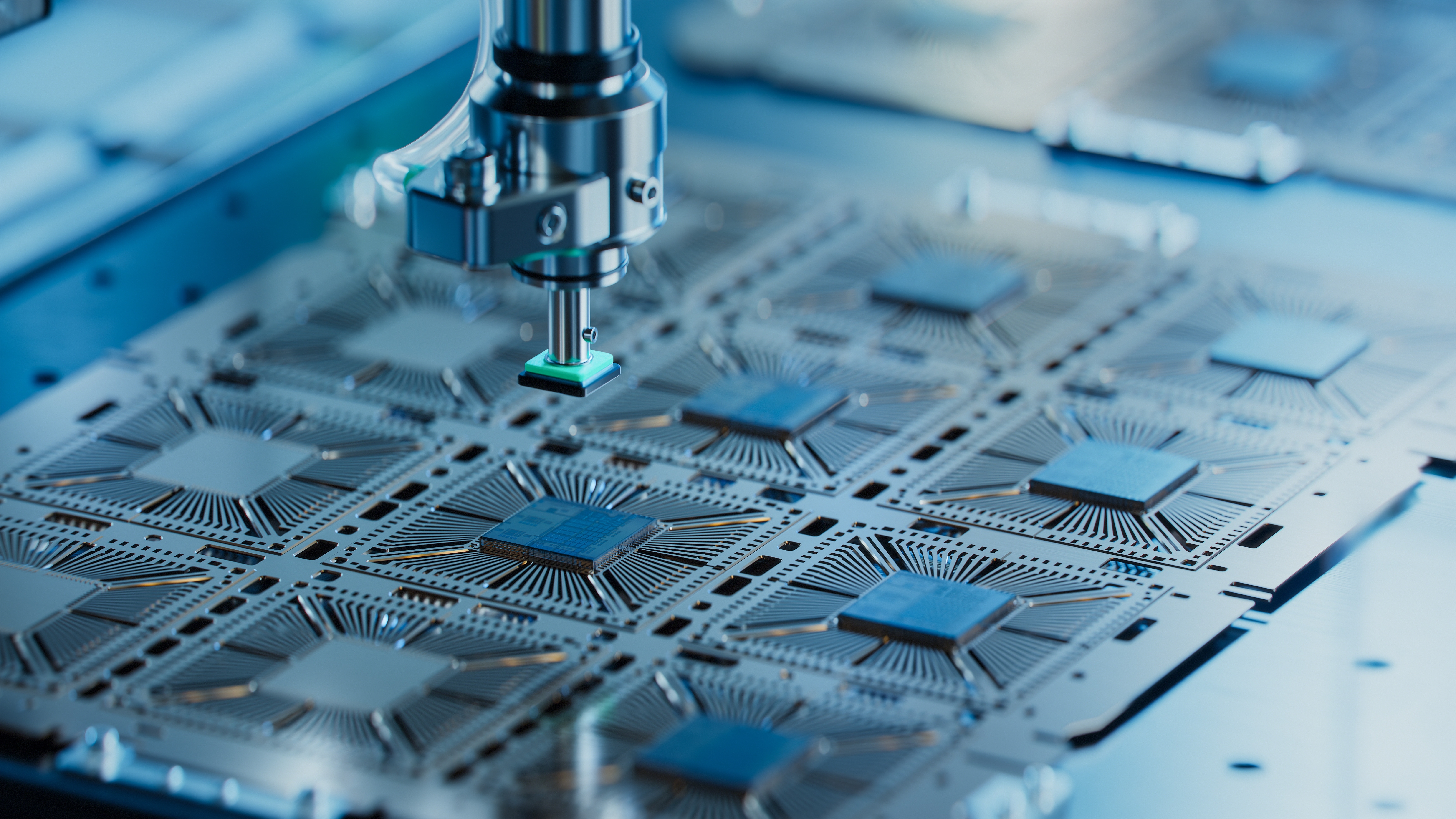

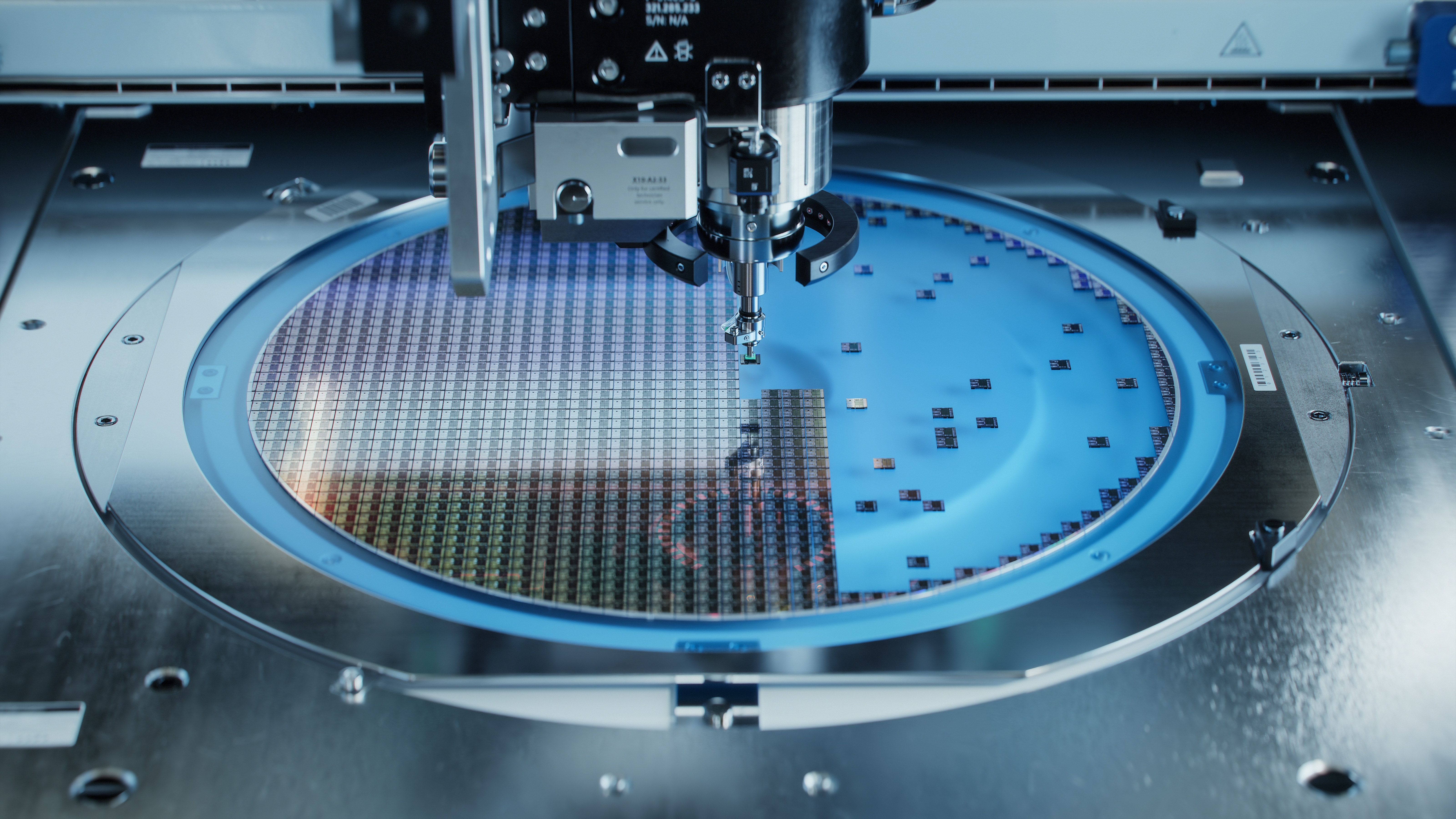

Semiconductor manufacturing is a highly complex process, operating non-stop, 24/7, 365 days a year. Each wafer undergoes over 1,000 structuring steps, utilizing hundreds of specialized production tools. These intricate processes generate massive volumes of production data daily, which serve as the foundation for implementing innovative tools and methods like EdgeAI.

Some of the key challenges in semiconductor manufacturing include:

- Unprecedented complexity: Hundreds of individual process steps are required to produce a single semiconductor chip.

- Domain-specific expertise: Teams often operate within well-defined technical domains, limiting cross-functional insights.

- Massive data generation: Managing and analyzing the sheer volume of production data is a formidable task.

- Resource efficiency: Optimizing resource utilization remains critical to maintaining profitability and sustainability.

Unlocking the Future with Edge AI

By addressing these challenges, Infineon is paving the way for smarter, more efficient, and sustainable manufacturing processes. Edge AI holds the potential to revolutionize quality management in the semiconductor industry, enabling manufacturers to harness data-driven insights and stay ahead in an increasingly competitive market.

The journey towards smarter semiconductor manufacturing is just beginning, and Infineon’s commitment to innovation and sustainability positions it as a leader in this transformative era.

Leave a Reply